Evaluate your biocides efficiency

Our testing loop in renewed environment belonging to evaluate antimicrobial treatments (biocides) against biofilms, and their safety on materials. Developed by Corrodys, and in collaboration with TOTAL, this tool also allows you to test the resistance of your material face to MIC.

Our testing loop in renewed environment belonging to evaluate antimicrobial treatments (biocides) against biofilms, and their safety on materials. Developed by Corrodys, and in collaboration with TOTAL, this tool also allows you to test the resistance of your material face to MIC.

![]() En savoir plus sur notre prestation de test d’évaluation de l’efficacité de substances biocides.

En savoir plus sur notre prestation de test d’évaluation de l’efficacité de substances biocides.

Objectives

-

Evaluate antimicrobial treatment effectiveness, preventive and curative, on biofilms (in terms of reduction of microorganisms and recolonization after treatment)

-

Check the safety of biocide treatments on corrosion of materials

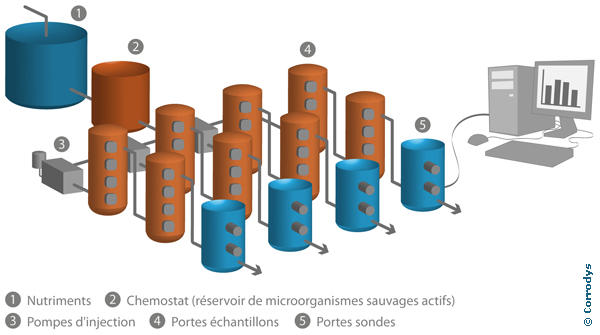

The loop’s operation

We take representative samples of your metallic structure and place them in the loop. The medium circulating in the loop is enriched with microorganisms naturally present in your processes. Then, Biofilms are developing on your samples.

We take representative samples of your metallic structure and place them in the loop. The medium circulating in the loop is enriched with microorganisms naturally present in your processes. Then, Biofilms are developing on your samples.

Next, we inject the antimicrobial products to evaluate their effectiveness on biofilms. So you will be able to choose the more appropriate and efficient biocide to treat and maintain your structure integrity.

Adjustable loop, close to your operating conditions

To fit to your operating conditions, you can choose :

- The testing medium: we facilitate the development of “natural” microorganisms which represent a potential threat for your material and which are already present in your operating conditions (seawater, freshwater or process water)

- Air conditions: according to microorganisms targeted and your structure, the loop can run with or without oxygen (N2, CO2, mix N2/CO2, etc.)

- Temperature: the testing circuits are placed in an incubator which allows to regulate the temperature between 30°C and 60°C

- Antimicrobial treatment: We can test biocides, a mix of biocides and other treatments (corrosion inhibitor, etc.) to evaluate their compatibility, treatment conditions (frequency, period between injection, etc.)

Example of test realized with the loop

Qualification/validation of biocides: biofilms have been created on carbon steel samples immersed in seawater enriched in sulfidogenic flora. The biocides effectiveness, and their corrosion/anticorrosion impact, has been estimate. ).